Abstract

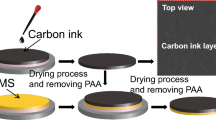

Liquid metal (LM) eutectic gallium–indium (EGaIn) possesses the ductility of a polymer and the conductivity of metal materials, making it a promising material for flexible electronics. Fabricating LM-based circuits is challenging because of the large surface tension of EGaIn. However, the circuit can be fabricated on various substrates using an additive printing process based on the principle of ultrasonic resonance. To improve the wettability between the LM and a substrate material, LM nanoparticles/carbon nanotubes (LMP/CNT) composite nano-ink was prepared, which has excellent colloidal stability and biocompatibility. A conductive circuit was realized by attaching CNTs to LMPs for imparting intrinsic electrical conductivity. Subsequently, flexible polydimethylsiloxane (PDMS) was used as the substrate, and a flexible pressure sensor with a response time of 103 ms was produced. This study introduces fabrication strategies for a flexible pressure sensor based on LMP/CNT composite nano-ink and additive printing processes, providing enormous possibilities for the application of LM in the field of printed electronics.

Similar content being viewed by others

Availability of Data and Materials

Data and materials will be made available on request.

Code Availability

Not applicable.

References

L.Y. Lan, J.F. Ping, J.Q. Xiong, and Y.B. Ying, Sustainable natural bio-origin materials for future flexible devices. Adv. Sci. 9(15), 34 (2022). https://doi.org/10.1002/advs.202200560.

T. Cheng, Y.Z. Zhang, W.Y. Lai, and W. Huang, Stretchable thin-film electrodes for flexible electronics with high deformability and stretchability. Adv. Mater. 27(22), 3349 (2015). https://doi.org/10.1002/adma.201405864.

B.W. Zhu, H. Wang, W.R. Leow, Y.R. Cai, X.J. Loh, M.Y. Han, and X.D. Chen, Silk fibroin for flexible electronic devices. Adv. Mater. 28(22), 4250–4265 (2016). https://doi.org/10.1002/adma.201504276.

A. Rafique, I. Ferreira, G. Abbas, and A.C. Baptista, Recent advances and challenges toward application of fibers and textiles in integrated photovoltaic energy storage devices. Nano-Micro Lett. 15(1), 58 (2023). https://doi.org/10.1007/s40820-022-01008-y.

X. Chen, X. Han, and Q.D. Shen, PVDF-based ferroelectric polymers in modern flexible electronics. Adv. Electron Mater. 3(5), 18 (2017). https://doi.org/10.1002/aelm.201600460.

M. Li, C.Q. Miao, M.H. Zou, J.H. Guo, H.Z. Wang, M. Gao, H.C. Zhang, and Z.F. Deng, The development of stretchable and self-repairing materials applied to electronic skin. Front. Chem. 11, 5 (2023). https://doi.org/10.3389/fchem.2023.1198067.

J. Lin, Z.R. Zhu, C.F. Cheung, F. Yan, and G.J. Li, Digital manufacturing of functional materials for wearable electronics. J. Mater. Chem. C. 8(31), 10587 (2020). https://doi.org/10.1039/d0tc01112f.

A.S. Almuslem, S.F. Shaikh, and M.M. Hussain, Flexible and stretchable electronics for harsh-environmental applications. Adv. Mater. Technol. 4(9), 18 (2019). https://doi.org/10.1002/admt.201900145.

Y.Q. Liu, K. He, G. Chen, W.R. Leow, and X.D. Chen, Nature-inspired structural materials for flexible electronic devices. Chem. Rev. 117(20), 12893 (2017). https://doi.org/10.1021/acs.chemrev.7b00291.

L. Gao, Flexible device applications of 2D semiconductors. Small 13(35), 15 (2017). https://doi.org/10.1002/smll.201603994.

Q. Wang, Y. Yu, and J. Liu, Preparations, characteristics and applications of the functional liquid metal materials. Adv. Eng. Mater. 20(5), 21 (2018). https://doi.org/10.1002/adem.201700781.

B.Y. Ping, G.X. Zhou, Z.H. Zhang, and R. Guo, Liquid metal enabled conformal electronics. Front. Bioeng. Biotechnol. 11, 19 (2023). https://doi.org/10.3389/fbioe.2023.1118812.

J. Park, D.H. Han, and J.K. Park, Towards practical sample preparation in point-of-care testing: user-friendly microfluidic devices. Lab. Chip. 20(7), 1191–1203 (2020). https://doi.org/10.1039/d0lc00047g.

J. Park, Y. Lee, H. Lee, and H. Ko, Transfer printing of electronic functions on arbitrary complex surfaces. ACS Nano. 14(1), 12–20 (2020). https://doi.org/10.1021/acsnano.9b09846.

M. Wang, C. Ma, P.C. Uzabakiriho, X. Chen, Z.R. Chen, Y. Cheng, Z.R. Wang, and G. Zhao, Stencil printing of liquid metal upon electrospun nanofibers enables high-performance flexible electronics. ACS Nano. 15(12), 19364–19376 (2021). https://doi.org/10.1021/acsnano.1c05762.

G.G. Guymon and M.H. Malakooti, Multifunctional liquid metal polymer composites. J. Polym. Sci. 60(8), 1300–1327 (2022). https://doi.org/10.1002/pol.20210867.

M. Hassan, G. Abbas, N. Li, A. Afzal, Z. Haider, S. Ahmed, X.R. Xu, C.F. Pan, and Z.C. Peng, Significance of flexible substrates for wearable and implantable devices: recent advances and perspectives. Adv. Mater. Technol. 7(3), 45 (2022). https://doi.org/10.1002/admt.202100773.

Z.Z. Hou, H. Lu, Y. Li, L.X. Yang, and Y. Gao, Direct ink writing of materials for electronics-related applications: a mini review. Front. Mater. 8, 8 (2021). https://doi.org/10.3389/fmats.2021.647229.

Y.S. Rim, S.H. Bae, H.J. Chen, N. De Marco, and Y. Yang, Recent progress in materials and devices toward printable and flexible sensors. Adv. Mater. 28(22), 4415–4440 (2016). https://doi.org/10.1002/adma.201505118.

N. Ochirkhuyag, R. Matsuda, Z.H. Song, F. Nakamura, T. Endo, and H. Ota, Liquid metal-based nanocomposite materials: fabrication technology and applications. Nanoscale 13(4), 2113–2135 (2021). https://doi.org/10.1039/d0nr07479a.

J.W. Boley, E.L. White, and R.K. Kramer, Mechanically sintered gallium–indium nanoparticles. Adv. Mater. 27(14), 2355–2360 (2015). https://doi.org/10.1002/adma.201404790.

Y.L. Lin, C. Cooper, M. Wang, J.J. Adams, J. Genzer, and M.D. Dickey, Handwritten, soft circuit boards and antennas using liquid metal nanoparticles. Small 11(48), 6397–6403 (2015). https://doi.org/10.1002/smll.201502692.

M.A. Rahim, F. Centurion, J.L. Han, R. Abbasi, M. Mayyas, J. Sun, M.J. Christoe, D. Esrafilzadeh, F.M. Allioux, M.B. Ghasemian, J. Yang, J.B. Tang, T. Daeneke, S. Mettu, J. Zhang, M.H. Uddin, R. Jalili, and K. Kalantar-Zadeh, Polyphenol-induced adhesive liquid metal inks for substrate-independent direct pen writing. Adv. Funct. Mater. 31(10), 12 (2021). https://doi.org/10.1002/adfm.202007336.

M.Y. Zhang, G.Q. Li, L. Huang, P.H. Ran, J.P. Huang, M. Yu, H.Y. Yuqian, J.H. Guo, Z.Y. Liu, and X. Ma, Versatile fabrication of liquid metal nano-ink based flexible electronic devices. Appl. Mater. Today 22, 9 (2021). https://doi.org/10.1016/j.apmt.2020.100903.

G.H. Lee, H. Woo, C. Yoon, C.Q. Yang, J.Y. Bae, W. Kim, D.H. Lee, H.M. Kang, S. Han, S.K. Kang, S. Park, H.R. Kim, J.W. Jeong, and S. Park, A personalized electronic tattoo for healthcare realized by on-the-spot assembly of an intrinsically conductive and durable liquid-metal composite. Adv. Mater. 34(32), 10 (2022). https://doi.org/10.1002/adma.202204159.

Y. Jo, J.H. Hwang, S.S. Lee, S.Y. Lee, Y.S. Kim, D.G. Kim, Y. Choi, and S. Jeong, Printable self-activated liquid metal stretchable conductors from polyvinylpyrrolidone-functionalized eutectic gallium indium composites. ACS Appl. Mater. Interfaces 14(8), 10747–10757 (2022). https://doi.org/10.1021/acsami.1c20185.

T.R. Lear, S.H. Hyun, J.W. Boley, E.L. White, D.H. Thompson, and R.K. Kramer, Liquid metal particle popping: macroscale to nanoscale. Extreme Mech. Lett. 13, 126–134 (2017). https://doi.org/10.1016/j.eml.2017.02.009.

U. Park, K. Yoo, and J. Kim, Development of a MEMS digital accelerometer (MDA) using a microscale liquid metal droplet in a microstructured photosensitive glass channel. Sens Actuator A Phys. 159(1), 51–57 (2010). https://doi.org/10.1016/j.sna.2010.02.011.

M.D. Dickey, R.C. Chiechi, R.J. Larsen, E.A. Weiss, D.A. Weitz, and G.M. Whitesides, Eutectic gallium–indium (EGaIn): a liquid metal alloy for the formation of stable structures in microchannels at room temperature. Adv. Funct. Mater. 18(7), 1097–1104 (2008). https://doi.org/10.1002/adfm.200701216.

L.T. Yi and J. Liu, Liquid metal biomaterials: a newly emerging area to tackle modern biomedical challenges. Int. Mater. Rev. 62(7), 415–440 (2017). https://doi.org/10.1080/09506608.2016.1271090.

S.L.Z. Liu, M.C. Yuen, E.L. White, J.W. Boley, B.W. Deng, G.J. Cheng, and R. Kramer-Bottiglio, Laser sintering of liquid metal nanoparticles for scalable manufacturing of soft and flexible electronics. ACS Appl. Mater. Interfaces 10(33), 28232–28241 (2018). https://doi.org/10.1021/acsami.8b08722.

Z. Qin, Z. Yi, and L. Jing, Direct writing of electronics based on alloy and metal (DREAM) ink: a newly emerging area and its impact on energy, environment and health sciences. Front Energy 6(4), 311–340 (2012). https://doi.org/10.1007/s11708-012-0214-x.

R.J. Slaughter, R.W. Mason, D.M.G. Beasley, J.A. Vale, and L.J. Schep, Isopropanol poisoning. Clin. Toxicol. 52(5), 470–478 (2014). https://doi.org/10.3109/15563650.2014.914527.

M. Schongut, D. Smrcka, and F. Stepanek, Experimental and theoretical investigation of the reactive granulation of sodium carbonate with dodecyl–benzenesulfonic acid. Chem. Eng. Sci. 86, 2–8 (2013). https://doi.org/10.1016/j.ces.2012.01.003.

X.L. He, J. Zhou, L.Z. Meng, J.X. Liu, X.B. Wang, S.X. Zhang, W.C. Li, and L.B. Yuan, High sensitivity strain sensor based on micro-helix micro taper long period fiber grating. IEEE Photonics Technol. Lett. 34(8), 432–435 (2022). https://doi.org/10.1109/lpt.2022.3164640.

Acknowledgments

The financial contributions are gratefully acknowledged. This work was financially supported by the Science and Technology Project of Jiaxing (2022AY10005), Science and Technology Project of Jiaxing (2019AY11018), and General scientific research project of Zhejiang Education Department (Y202250333).

Funding

This research is funded by the Science and Technology Project of Jiaxing (2022AY10005), Science and Technology Project of Jiaxing (2019AY11018), and General scientific research project of Zhejiang Education Department (Y202250333)

Author information

Authors and Affiliations

Contributions

T.Y.: investigation, data curation, writing—original draft preparation, writing—review and editing, formal analysis. J.Y.F.: conceptualization, investigation, methodology, validation, data curation, writing—review and editing, resources, supervision, project administration. H.Z.A.: investigation, data curation, formal analysis. P.C.: investigation, data curation, formal analysis. T.S.: formal analysis. B.X.: review and editing, formal analysis, funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent to Participate

Not applicable

Consent for Publication

Not applicable

Ethics Approval

Not applicable

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

11664_2023_10841_MOESM1_ESM.pdf

Supplementary file 1 SEM image of LM in different ultrasonic power and time, SEM image of CNT in LMP ink. Without dispersed, Dispersed, image of printed patterns on different substrates, PET, PI and PDMS, image of printed conductive film surface. Conductivity of conductive films with different thickness. the pressure test of conductive films with different thicknesses printed on PDMS.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, T., Feng, J., Ao, H. et al. A Composite Nano-ink of Liquid Metal Nanoparticles and Carbon Nanotubes for the Fabrication of Flexible Pressure Sensors. J. Electron. Mater. 53, 652–660 (2024). https://doi.org/10.1007/s11664-023-10841-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10841-9