Abstract

In the early nineties, microelectromechanical systems (MEMS) technology has been still in its infancy. As silicon (Si) is not a transducer material, it was clear at the very beginning that mechanically active materials had to be introduced to MEMS in order to enable functional microdevices with actuation capability beyond electrostatics. At that time, shape memory alloys (SMAs) have been available in bulk form, mainly as SMA wires and SMA plates. On the macro scale, these materials show highest work densities compared to other actuation principles in the order of 107 J/m3, which stimulated research on the integration of SMA to MEMS. Subsequently, two approaches for producing planar materials have been initiated (1) magnetron sputtering of SMA thin films and (2) the integration of rolled SMA foils, which both turned out to be very successful creating a paradigm change in microactuation technology. The following review covers important milestones of the research and development of SMA foil-based microactuators including materials characterization, design engineering, technology, and demonstrator development as well as first commercial products.

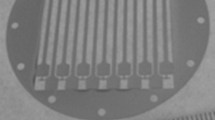

(Reproduced with permission from Elsevier [15])

(Reproduced with permission from [20])

(Reproduced with permission from [35])

(reprinted with permission from IOP Publishing [36])

(reprinted with permission from IEEE XPlore Digital Library [26])

(Reproduced with permission from [30])

(Reproduced with permission from Elsevier [47])

(Reproduced with permission from [36])

(Reproduced with permission from [36])

(Reproduced with permission from [61])

(Reproduced with permission from [63])

Similar content being viewed by others

References

Miyazaki S, Fu YQ, Huang WM (eds) (2009) Thin film shape memory alloys: fundamentals and device applications. Cambridge University Press, Cambridge

Otsuka K, Wayman CM (1999) Shape memory materials. Cambridge University Press, Cambridge

Kohl M, Schmitt M, Backen A, Schultz L, Krevet B, Fähler S (2014) Ni-Mn-Ga shape memory nanoactuation. Appl Phys Lett 104:43111

Kohl M, Brugger D, Ohtsuka M, Takagi T (2004) A novel actuation mechanism on the basis of ferromagnetic SMA thin films. Sens Actuators A 114:445–450

Kohl M (2004) Shape memory microactuators. Springer, Heidelberg

Howe RT, Muller RS, Gabriel KJ, Trimmer WS (1990) Silicon micromechanics: sensors and actuators on a chip. IEEE Spectr 7:29–31

Menz W, Mohr J, Paul O (2007) Microsystem technology. Wiley, New York

Feynman RP (1992) There is plenty of room at the bottom. J MEMS 1:60–66

Buehler WJ, Gilfrich JV, Wiley RC (1963) Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J Appl Phys 34:1475

Vasil’ev AN, Buchel’nikov VD, Takagi T, Khovailo VV, Estrin E (2003) Shape memory ferromagnets. Phys Uspekhi 46:559–588

Faran E, Shilo D (2015) Ferromagnetic shape memory alloys—challenges, applications, and experimental characterization. Exp Tech 40:1005–1031

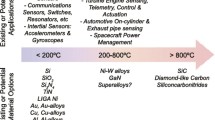

Ma J, Karaman I, Noebe RD (2010) High temperature shape memory alloys. Int Mater Rev 55:257–315

Kim HY, Ikehara Y, Kim JI, Hosoda H, Miyazaki S (2006) Martensitic transformation, shape memory effect and superelasticity of Ti–Nb binary alloys. Acta Mater 54:2419–2429

Khantachawana A, Miyazaki S, Iwai H, Kohl M (1999) Effect of heat-treatment and anisotropy of transformation strain in Ti-Ni-Fe rolled thin plates. Mater Sci Eng 273–275:763–768

Kitamura K, Miyazaki S, Iwai H, Kohl M (1999) Effect of rolling reduction on the deformation texture and anisotropy of transformation strain in Ti-50.2at.%Ni thin plates. Mater Sci Eng 273–275:758–762

Kitamura K, Miyazaki S, Iwai H, Kohl M (1997) Effect of heat treatment on the texture in rolled TiNi thin plates. In Proc. SMST 97, Pacific Grove, California, USA

Ossmer H, Lambrecht F, Gultig M, Chluba C, Quandt E, Kohl M (2014) Evolution of temperature profiles in TiNi films for elastocaloric cooling. Acta Mater 81:9–20

Wendler F, Ossmer H, Chluba C, Quandt E, Kohl M (2017) Mesoscale simulation of elastocaloric cooling in SMA films. Acta Mater 136:105–117

Ossmer H, Miyazaki S, Kohl M (2015) The elastocaloric effect in TiNi-based foils. Mater Today Proc 2:971–974

Ossmer H, Miyazaki S, Kohl M (2014) The elastocaloric effect in NiTi- based Foils. In: International conference on martensitic transformations (ICOMAT)

Miyazaki S, Otsuka K (1986) Deformation and transition behavior associated with the R-phase in Ti-Ni alloys. Metall Trans A 17:53–63

Kohl M, Gueltig M, Pinneker V, Yin R, Wendler F (2014) Magnetic shape memory microactuators. Micromachines 5:1135–1160

Fu Y, Du H, Huang W, Zhang S, Hu M (2004) TiNi-based thin films in MEMS applications: a review. Sens Actuators A 112:395–408

Yin R, Wendler F, Krevet B, Kohl M (2016) A magnetic shape memory microactuator with intrinsic position sensing. Sens Actuators A 246:48–57

Niklaus F, Stemme G, Lu J-Q, Gutmann RJ (2006) Adhesive wafer bonding. J Appl Phys 99:31101

Braun S, Sandstrom N, Stemme G, van der Wijngaart W (2009) Wafer-scale manufacturing of bulk shape-memory-alloy microactuators based on adhesive bonding of titanium-nickel sheets to structured silicon wafers. J MEMS 18:1309–1317

Sandström N, Grund SBT, Stemme G, Kohl M, van der Wijngaart W (2008) Wafer-scale manufacturing of robust trimorph bulk SMA microactuators. In: 11th International conference on new actuators ACTUATOR, pp 382–385

Grund T, Barth J, Kohl M (2010) Vorrichtung und Verfahren zum selektiven Übertragen einer mikrostrukturierten Komponente, (Setup and procedure for selective transfer of a micromachined component), Patent DE 10 2009 017 306.4

Grund T, Megnin C, Barth J, Kohl M (2009) Batch fabrication of shape memory actuated polymer microvalves by transfer bonding techniques. J Microelectron Electron Packag 6:1–9

Grund T, Guerre R, Despont M, Kohl M (2008) Transfer bonding technology for batch fabrication of SMA microactuators. Eur Phys J Spec Top 158:237–242

Grund T, Cuntz T, Kohl M (2008) Batch fabrication of polymer microsystems with shape memory microactuators. In: Proceedings of MEMS 08, Tucson, USA, pp 423–426

Pfeifer R, Herzog D, Hustedt M, Barcikowski S (2010) Pulsed Nd:YAG laser cutting of NiTi shape memory alloys—influence of process parameters. J Mater Process Technol 210:1918–1925

Li C, Nikumb S, Wong F (2006) An optimal process of femtosecond laser cutting of NiTi shape memory alloy for fabrication of miniature devices. Opt Lasers Eng 44:1078–1087

Kohl M, Skrobanek KD, Allen DM (1996) Mechanical characterization of shape memory micromaterials. In: Microlithography and metrology in micromachining II

Kohl M, Skrobanek KD, Goh CM, Allen DM (1996) Microlithography and metrology in micromachining II. In: Proceedings of international conference on microlithogr. metrol. micromach. II, Austin, Texas, USA, vol Proceeding, pp 108–118

Megnin C, Kohl M (2014) Shape memory alloy microvalves for a fluidic control system. JMM 24:25001

Breidert J, Michutta J, Siegert W, Neuking K, Welp EG (2013) Soldered joints for shape memory components. In: SMST 2013, Prague, Czech Republic, p 209ff

http://www.indium.com/medical/soldering-to-nitinol/, “2017-08-29.”

Zhou YN (2008) Microjoining and nanojoining. Woodhed Publishing Limited, Cambridge (England)

Mirshekari GR, Saatchi A, Kermanpur A, Sadrnezhaad SK (2013) Optics & laser technology laser welding of NiTi shape memory alloy: comparison of the similar and dissimilar joints to AISI 304 stainless steel. Opt Laser Technol 54:151–158

Gugel H, Schuermann A, Theisen W (2008) Laser welding of NiTi wires. Mater Sci Eng A 482:668–671

Zeng Z, Panton B, Oliveira JP, Han A, Zhou YN (2015) Dissimilar laser welding of NiTi shape memory alloy and copper. Smart Mater Struct 24:125036

Tusek J, Engelbrecht K, Eriksen D, Olio S, Tusek J, Pryds N (2016) A regenerative elastocaloric heat pump. Nat Energy 1:16134

Johnson AD, Ray CA (1994) Shape memory alloy film actuated microvalve, Pat. (US5325880 A)

Fischer AC, Gradin H, Braun S, Schröder S, Stemme G, Niklaus F (2011) Wafer-level integration of NiTi shape memory alloy wires for the fabrication of microactuators using standard wire bonding technology. In: 2011 IEEE 24th international conference on micro electro mechanical systems, pp 348–351

Kohl M, Just E, Pfleging W, Miyazaki S (2000) SMA microgripper with integrated antagonism. Sens Actuators A 83:208–213

Kohl M, Krevet B, Just E (2002) SMA microgripper system. Sens Actuators A 97–98:646–652

Johnson AD (1991) Vacuum-deposited TiNi shape memory film: characterization and applications in microdevices. JMM 1(1):34

Kohl M, Krevet B (2002) 3D simulation of a shape memory microactuator. Mater Trans 43:1030–1036

Krevet B, Kohl M (2008) Modeling and FEM simulation of shape memory microactuators. Mater Sci Forum 583:229–256

Kohl M, Skrobanek KD, Miyazaki S (1999) Development of stress-optimised shape memory microvalves. Sens Actuators 72:243–250

Skrobanek KD, Kohl M, Miyazaki S (1997) Stress-optimised shape memory devices for the use in microvalves. J Phys IV Fr 7:1–6

Kohl M, Göbes J, Krevet B (2000) Normally-closed shape memory microvalve. Int J Appl Electromagn Mech 12:71–77

Megnin C, Barth J, Kohl M (2012) A bistable SMA microvalve for 3/2-way control. Sens Actuators A 188:285–291

Barth J, Megnin C, Kohl M (2012) A bistable shape memory alloy microvalve with magnetostatic latches. J MEMS 21:76–84

Barth J, Megnin C, Kohl M (2011) A bistable shape memory microvalve. In: Proceedings of IEEE MEMS 2011, Cancun, Mexico, pp 1067–1070

Kohl M, Liu Y, Dittmann D (2004) A polymer-based microfluidic controller. In: International conference on micro electro mechanical systems, MEMS, pp 288–291

Liu Y, Dürr S, Dittmann D, Kohl M (2002) A modular integrated microfluidic controller. In: Borgmann H (ed) Proceedings of actuator 02, Bremen, Germany, pp 231–234

Megnin C, Brammer M, Luckert H, Kohl M (2012) SMA microvalves with plug-in interface for a modular fluidic backplane. In: Borgmann H (ed) Proceedings of actuator 12, Bremen, Germany, pp 510–513

Braun S, Haasl S, Sadoon S, Ridgeway AS, van der Wijngaart W, Stemme G (2005) Small footprint knife gate microvalves for large flow control. In: Proceedings of transducers 05, Seoul, Korea, pp 329–332

Gradin H, Braun S, Stemme G, van der Wijngaart W (2012) SMA microvalves for very large gas flow control manufactured using wafer-level eutectic bonding. IEEE Trans Ind Electron 59:4895–4906

www.memetis.com, “(25.08.17).”

Barth J, Krevet B, Kohl M (2010) A bistable shape memory microswitch with high energy density. Smart Mater Struct 19:94004

Barth J, Kohl M (2010) A bistable magnetically enhanced shape memory microactuator with high blocking forces. Phys Procedia 10:189–196

Cui J et al (2012) Demonstration of high efficiency elastocaloric cooling with large T using NiTi wires. Appl Phys Lett 101:73904

Wang X, Verlinden B, Van Humbeeck J (2015) Deformation behavior after stress-induced martensite transformation in a Ti-50.8 at.% Ni alloy. MATEC Web Conf 33:3018

Tan G, Liu Y, Sittner P, Saunders M (2004) Lüders-like deformation associated with stress-induced martensitic transformation in NiTi. Scr Mater 50:193–198

Brinson LC, Schmidt I, Lammering R (2004) Stress-induced transformation behavior of a polycrystalline NiTi shape memory alloy: micro and macromechanical investigations via in situ optical microscopy. J Mech Phys Solids 52:1549–1571

Ossmer H, Wendler F, Gueltig M, Lambrecht F, Miyazaki S, Kohl M (2016) Energy-efficient miniature-scale heat pumping based on shape memory alloys. Smart Mater Struct 25:85037

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kohl, M., Ossmer, H., Gueltig, M. et al. SMA Foils for MEMS: From Material Properties to the Engineering of Microdevices. Shap. Mem. Superelasticity 4, 127–142 (2018). https://doi.org/10.1007/s40830-017-0144-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-017-0144-x