Abstract

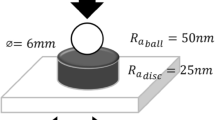

The lubrication mechanism of nanoinorganic particles during friction process has been widely investigated. However, the physical adsorption action mechanism between the nanoparticles (after modification) and friction pairs has so far never been studied in detail. In this study, the various concentrations of polyisobutyleneamine succinimide (PIBS) by weight in paraffin oil were applied to study their effect on the tribological behaviors of nano-MoS2 oil. And the tribological results were further discussed to understand the lubricating action mechanism of nano-MoS2 particles additive. The results show that the tribological behavior of modified nanoparticles was significantly influenced by PIBS concentration. The COF reduced from 0.139 to 0.090 with low PIBS concentration (less than 0.1 wt%), while the COF reduced to 0.126 with higher PIBS concentration (more than 0.2 wt%). By scanning electron microscopic (SEM) and energy-dispersive X-ray spectroscopy, some mechanisms likely related to this interesting results are revealed. It is identified that: (1) production of MoS2 tribofilm on steel surface reduces the COF and wear, (2) wear scar is smooth with low PIBS concentration, while it shows plowing wear with high PIBS concentration, (3) the MoS2 tribofilm is found by SEM on the wear scar of the nano oil with 0.05 wt% PIBS. A three-step lubricating action mechanism of the modified nano-MoS2 particles has been proposed as an explanation for the interesting results. The results indicate that physical adsorption provide an initial action for nanoparticle lubricant to form tribofilm in boundary lubrication.

Similar content being viewed by others

References

Zhang, Z.J., Zhang, J., Xue, Q.J.: Synthesis and characterization of a molybdenum disulfide nanocluster. J. Phys. Chem. 98, 12973–12977 (1994)

Tannous, J., Dassenoy, F., Lahouij, I., Le-Mogne, T., Vacher, B., Bruhács, A., Tremel, W.: Understanding the tribochemical mechanisms of IF-MoS2 nanoparticles under boundary lubrication. Tribol. Lett. 41, 55–64 (2011)

Rabaso, P., Dassenoy, F., Ville, F., Diaby, M., Vacher, B., Le-Mogne, T., Belin, M., Cavoret, J.: An investigation on the reduced ability of IF-MoS2 nanoparticles to reduce friction and wear in the presence of dispersants. Tribol. Lett. 55, 503–516 (2014)

Ratoi, M., Niste, V.B., Walker, J., Zekonyte, J.: Mechanism of action of WS2 lubricant nanoadditives in high-pressure contacts. Tribol. Lett. 52, 81–91 (2013)

Martin, J.M., Ohmae, N.: Nanolubricants. Wiley, London (2008)

Joly-Pottuz, L., Dassenoy, F., Belin, M., Vacher, B., Martin, J.M., Fleischer, N.: Ultralow-friction and wear properties of IF-WS2 under boundary lubrication. Tribol. Lett. 18, 477–485 (2005)

Wu, Y.Y., Tsui, W.C., Liu, T.C.: Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 262, 819–825 (2007)

Rapoport, L., Leshchinsky, V., Lvovsky, M., Nepomnyashchy, O., Volovik, Y., Tenne, R.: Mechanism of friction of fullerenes. Ind. Lubr. Tribol. 54, 171–176 (2002)

Zhou, J.F., Yang, J.J., Zhang, Z.J., Liu, W.M., Xue, Q.J.: Study on the structure and tribological properties of surface-modified Cu nanoparticles. Mater. Res. Bull. 34, 1361–1367 (1999)

Liu, W.M., Xue, Q.J., Zhou, J.F., Zhang, Z.J.: Antiwear properties of nanoparticles and application study of nanoparticles as additives in the wear-repairing agent. China Surf. Eng. 14, 21–23 (2001)

Liu, G., Li, X., Qin, B., Xing, D., Guo, Y., Fan, R.: Investigation of the mending effect and mechanism of copper nano-particles on a tribologically stressed surface. Tribol. Lett. 17, 961–966 (2004)

Rapoport, L., Leshchinsky, V., Lapsker, I., Volovik, Y., Nepomnyashchy, O., Lvovsky, M., Popovitz-Biro, R., Feldman, Y., Tenne, R.: Tribological properties of WS2 nanoparticles under mixed lubrication. Wear 255, 785–793 (2003)

Tevet, O., Von-Huth, P., Popovitz-Biro, R., Rosentsveig, R., Wagner, H.D., Tenne, R.: Friction mechanism of individual multilayered nanoparticles. Proc. Natl. Acad. Sci. 108, 19901–19906 (2011)

Bakunin, V.N., Suslov, A.Y., Kuzmina, G.N., Parenago, O.P., Topchiev, A.V.: Synthesis and application of inorganic nanoparticles as lubricant components—a review. J. Nanopart. Res. 6, 273–284 (2004)

Pawlak, Z.: Tribochemistry of Lubricating Oils. Elsevier, Amsterdam (2003)

Aralihalli, S., Biswas, S.K.: Grafting of dispersants on MoS2 nanoparticles in base oil lubrication of steel. Tribol. Lett. 49, 61–76 (2013)

Willermet, P.A.: Some engine oil additives and their effects on antiwear film formation. Tribol. Lett. 5, 41–47 (1998)

Harris, T.A., Kotzalas, M.N.: Advanced Concepts of Bearing Technology: Rolling Bearing Analysis. CRC Press, Boca Raton (2006)

Wu, H.X., Ho, J.K., Dong, G.N., Zhang, D.Y.: Friction reduction of pre-phosphating nanofilm on bearing steel by tricresyl phosphate pretreatment in boundary lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 229, 101–111 (2015)

Nagaraju, G., Tharamani, C.N., Chandrappa, G.T., Livage, J.: Hydrothermal synthesis of amorphous MoS2 nanofiber bundles via acidification of ammonium heptamolybdate tetrahydrate. Nanoscale Res. Lett. 2, 461–468 (2007)

Liu, S., Zhang, X., Shao, H., Xu, J., Chen, F., Feng, Y.: Preparation of MoS2 nanofibers by electrospinning. Mater. Lett. 73, 223–225 (2012)

Yu, J., Huang, X., Wu, C., Wu, X., Wang, G., Jiang, P.: Interfacial modification of boron nitride nanoplatelets for epoxy composites with improved thermal properties. Polymer 53, 471–480 (2012)

Nicholls, M.A., Do, T., Norton, P.R., Kasrai, M., Bancroft, G.M.: Review of the lubrication of metallic surfaces by zinc dialkyl-dithiophosphates. Tribol. Int. 38, 15–39 (2005)

Mangolini, F., Rossi, A., Spencer, N.D.: Reactivity of triphenyl phosphorothionate in lubricant oil solution. Tribol. Lett. 35, 31–43 (2009)

Schwarz, U.S., Komura, S., Safran, S.A.: Deformation and tribology of multi-walled hollow nanoparticles. Europhys. Lett. 50, 762–768 (2000)

Acknowledgments

The project was supported by the School-Enterprise Cooperation Project (Grant No. 20130412).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, H., Qin, L., Zeng, Q. et al. Understanding the Physical Adsorption Action Mechanism of MoS2 Nanoparticles in Boundary Lubrication with Different Polyisobutyleneamine Succinimide (PIBS) Concentrations. Tribol Lett 60, 26 (2015). https://doi.org/10.1007/s11249-015-0604-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0604-4