Abstract

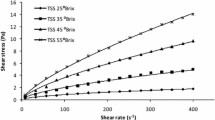

Dika kernels are known for their mucilaginous consistency, but limited work has been reported about it. This study investigated the flowing characteristics (share stress and viscosity) of the dika kernel and its soup; and this was assessed at specific temperatures (30, 50, 70 and 90) °C by the use of a viscometer. All samples behaved as non-Newtonian fluids. The bulk, tapped and loose densities of the powdered samples were obtained to evaluate the Carr index, Hausner ratio and porosity. The viscosity and shear stress of the reconstituted powder and soup samples as a function of the shear rate were investigated (30–90 °C). Dika kernel at its natural moisture content has excellent flowing property (1.118 Hausner ratio, 10.566 Carr index and 20.300% porosity), but increase in moisture content decreased this ability. The viscosity of the soup (165.789–14,546.341 mPa s) was higher than the reconstituted dika (69.831–206.240 mPa s) at all temperature studied. Shear stress was temperature-dependent, and Bingham and Power-law models gave the best predictions of flow.

Similar content being viewed by others

References

Abubakar UM, Sopade PA (1993) Rheological characterization of three nigerian traditional soups: Ewedu (Corchorus olitorius), Karkashi (Artemisia spp.) and Ogbono (Irvingia gabonensis) at different temperatures. Nig Food J 11:118–127

Akanbi CT (1992) Processing, physical and sensory characteristics of drum dried cowpea bean (Gbegiri) soup. Nig Food J 10:44–50

Alakali JS, Ijabo OJ, Satimehin AA (2003) Rheological characteristics of Canarium (Canarium Schweinfurhii) oil. J Pure Appl Sci 6(2):298–303

Ariahu CC, Risikat B, Tiamiyu OI (2001) Influence of soy flour and temperature on tilapia fish homogenate. Afr J Environ Stud 2:138–141

Awonorin SO (1993) Rheological and mechanical properties of B vitamin retention and sensory characteristics of sausage made from broiler chicken and guinea fowl. LWT 20:291–300

Carr RL (1965) Evaluating flow properties of solids. Chem Eng 72:163–168

Casson NA (1959) Flow equation for pigmented-oil suspension of the printing ink type. In: Mill CC (ed) Rheology of dispersed systems. Pergamon Press, New York

Chavan R, Kumar A, Basu S, Nema PK, Nalawade T (2015) Whey based tomato soup powder: rheological and color properties. Int J Agric Sci Res 5(4):301–313

Fasina OO (2006) Flow and physical properties of switchgrass, peanut hull and poultry litter. Trans ASABE 49:721–728

Fasogbon BM, Taiwo KA (2017) Modelling of the thermophysical properties of ground Dika kernel (Irvingia wombolu Vermoesen) as affected by temperature and moisture content. Asian Res J Agric 5(4):1–10

Fasogbon BM, Taiwo KA, Adeniran HA (2017) Sensory profiling of Ogbono (Irvingia wombolu) soup mix and its nutritional characterisation. Ann Food Sci Technol 18(4):552–563

Food and Agricultural Organization of the United Nations (FAO) (2003) Harvesting of non-wood forest products. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training 2000, Turkey, pp 325–334

Hausner HH (1967) Friction conditions in a mass of metal powder. Int J Powder Metal 3:7–13

Hooper D, Coughlan J, Mullen MR (2008) Structural equation modelling: guidelines for determining model fit. Electron J Bus Res Method 6(1):53–60

Jan S, Rafiq SI, Saxena DC (2015) Effect of physical properties on flow ability of commercial rice flour/powder for effective bulk handling. In: International conference on advanced engineering and technology, pp 1–5

Jinapong N, Suphantharika M, Jamnong P (2008) Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. J Food Eng 84(2):194–205

Keshani S, Luqman Chuah A, Russly AR (2012) Effect of temperature and concentration on rheological properties pomelo juice concentrates. Int Food Res J 19(2):553–562

Khan A, Saini CS (2016) Effect of roasting on physicochemical and functional properties of flaxseed flour. Cogent Eng 3(1145566):1–14

Laub C, Kuhl TL (2016) How bad is good? A critical look at the fitting of reflectivity models using the reduced chi square statistic (Online). University of California, Davis

Loisel C, Maache-Rezzoug Z, Esneaultt C, Doublier JL (2006) Effect of hydrothermal treatment on the physical and rheological properties of maize starches. J Food Eng 73:45–54

MacCallum RC, Browne MW, Sugawara HM (1996) Power analysis and determination of sample size for covariance structure modeling. Psychol Methods 1(2):130–149

Mohsenin NN (1986) Physical properties of plant and animal materials. Gordon and Breach Science Publishers, New York

Okezie BO, Bello AB (1988) Physicochemical and functional properties of winged bean flour and isolate compared with soy isolate. J Food Sci 53:450–455

Oladimeji O (2014) A parametric analysis of thermal processing of canned “Ogbono” soup from Irvingia gabonensis. Ph.D. thesis, University of Agriculture, Abeokuta, Nigeria. Available at: Prof. Awonorin Personal Library 2007

Prasad K, Yadav YS (2014) Chapter 6: characterisation of instant soup mix: in rice based vegetable supplemented functional instant soup mix and prepared soup behaviour: development and optimization. Scholar Press, Berlin, pp 158–197

Sahin S, Sumnu SG (2006) Physical properties of foods. Springer, Ankara

Singh RP, Heldman DR (2009) Introduction to food engineering, 4th edn. Elsevier, Amsterdam, p 155–161, 260

Steffe JF (1992) Rheological methods in food process engineering. Freeman Press, Michigan

Steffe JF (1996) Rheological methods in food process engineering, 2nd edn. Freeman Press, Michigan

Steiger JH (2007) Understanding the limitations of global fit assessment in structural equation modeling. Per Ind Differ 42(5):893–898

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix 1

Rheology data for reconstituted dika kernel

Temperature | Shear rate (1/s) | Shear stress (Pa) | Viscosity (mPa s) |

|---|---|---|---|

30 | 25.800 | 3.622 | 140.3875969 |

30 | 38.820 | 4.666 | 120.1957754 |

30 | 39.980 | 4.666 | 116.7083542 |

30 | 50.050 | 5.219 | 104.2757243 |

30 | 83.330 | 6.508 | 78.09912396 |

30 | 129.200 | 8.964 | 69.38080495 |

50 | 25.800 | 5.771 | 223.6821705 |

50 | 38.820 | 5.280 | 136.0123648 |

50 | 39.980 | 6.692 | 167.3836918 |

50 | 50.050 | 6.754 | 134.9450549 |

50 | 83.330 | 7.306 | 87.67550702 |

50 | 129.200 | 12.700 | 98.29721362 |

70 | 25.800 | 4.850 | 187.9844961 |

70 | 38.820 | 4.850 | 124.9356002 |

70 | 39.980 | 5.648 | 141.2706353 |

70 | 50.050 | 5.894 | 117.7622378 |

70 | 83.330 | 6.938 | 83.25933037 |

70 | 129.200 | 10.310 | 79.79876161 |

90 | 25.800 | 5.321 | 206.2403101 |

90 | 38.820 | 5.955 | 153.4003091 |

90 | 39.980 | 6.385 | 159.7048524 |

90 | 50.050 | 6.815 | 136.1638362 |

90 | 83.330 | 7.490 | 89.88359534 |

90 | 129.200 | 11.600 | 89.78328173 |

Appendix 2

Rheology data for Ogbono soup

Temperature | Shear rate (1/s) | Shear stress (Pa) | Viscosity (mPa s) |

|---|---|---|---|

30 | 25.800 | 12.150 | 470.9302326 |

30 | 38.820 | 14.980 | 385.8835652 |

30 | 39.980 | 11.110 | 277.8889445 |

30 | 50.050 | 16.330 | 326.2737263 |

30 | 83.330 | 18.230 | 218.7687508 |

30 | 129.200 | 21.420 | 165.7894737 |

50 | 25.800 | 9.824 | 380.7751938 |

50 | 38.820 | 11.170 | 287.7382792 |

50 | 39.980 | 12.770 | 319.4097049 |

50 | 50.050 | 12.090 | 241.5584416 |

50 | 83.330 | 15.650 | 187.8075123 |

50 | 129.200 | 19.030 | 147.2910217 |

70 | 25.800 | 14.300 | 554.2635659 |

70 | 38.820 | 16.330 | 420.6594539 |

70 | 39.980 | 18.600 | 465.2326163 |

70 | 50.050 | 18.230 | 364.2357642 |

70 | 83.330 | 21.120 | 253.450138 |

70 | 129.200 | 26.520 | 205.2631579 |

90 | 0.645 | 7.122 | 11041.86047 |

90 | 0.645 | 9.394 | 14564.34109 |

90 | 1.032 | 8.534 | 8269.379845 |

90 | 2.580 | 14.350 | 5562.015504 |

90 | 3.875 | 11.290 | 2913.548387 |

90 | 6.450 | 17.190 | 2665.116279 |

90 | 129.200 | 35.910 | 277.9411765 |

Rights and permissions

About this article

Cite this article

Fasogbon, B.M., Taiwo, K.A. Modelling the flowing behaviour of dika kernel powder and soup as affected by moisture content, physical and rheological properties. J Food Sci Technol 56, 4688–4695 (2019). https://doi.org/10.1007/s13197-019-03921-4

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03921-4