Abstract

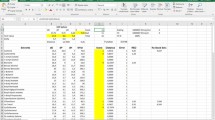

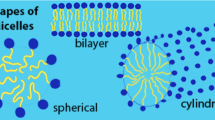

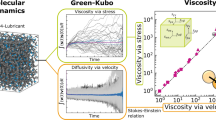

The paper describes a comparative assessment of viscosity–temperature curves for a number of model mixtures prepared from crude oil maltenes isolated from unstable oils (with island-type asphaltenes) and stable oils (with archipelago-type asphaltenes) with the addition of 5 wt % of individual n-alkanes (C10 or C23) and/or asphaltenes (native or foreign). All the viscosity–temperature curves consist of two distinct regions, namely a low-temperature region (10–30°C) and a high-temperature region (30–50°C), within which the behavior of oil systems is governed by the presence of solid paraffin crystals and the aggregation state of asphaltenes, respectively. It is assumed that, at high temperatures, the most critical factors responsible for the viscosity–temperature properties of oil systems are the asphaltene structural type (island or archipelago) and the propensity of the asphaltenes to flocculation or paraffin–asphaltene aggregation. It is further demonstrated that the flocculation of asphaltenes is accompanied by the entrapment of n-alkanes contained in the dispersion medium, and that the amounts trapped by island-type asphaltenes are higher.

Similar content being viewed by others

REFERENCES

Abivin, P., Taylor, S.D., and Freed, D., Energy Fuel, 2012, vol. 26, no. 6, pp. 3448–3461. https://doi.org/10.1021/ef300065h

Ilyin, S.O., Arinina, M.P., Polyakova, M.Y., Kulichikhin, V.G., and Malkin, A.Y., Fuel, 2016, vol. 186, pp. 157–167. https://doi.org/10.1016/j.fuel.2016.08.072

Visintin, R.F.G., Lapasin, R., Vignati, E., D’Antona, P., and Lockhart, T.P., Langmuir, 2005, vol. 21, no. 14, pp. 6240–6249. https://doi.org/10.1021/la050705k

Malkin, A.Y., Petrol. Chem., 2019, vol. 59, pp. 1092–1107. https://doi.org/10.1134/S0965544119100062

Aref, A.M., Fuel, 2022, vol. 316. Article 123372. https://doi.org/10.1016/j.fuel.2022.123372

Li, X., Chi, P., Guo, X., and Sun, Q., Fuel, 2019, vol. 255. Article 115825. https://doi.org/10.1016/j.fuel.2019.115825

Mullins, O.C., Betancourt, S.S., Cribbs, M.E., Dubost, F.X., Creek, J.L., Andres, A.B., and Venkataramanan, L., Energy Fuel, 2007, no. 21, pp. 2785–2794.

Lei, Y., Li, S., Liu, X., Wang, H., Zhu, H., Gao, Y., Peng, H., and Yu, P., J. Mol. Liq., 2022, vol. 365. Article 120132. https://doi.org/10.1016/j.molliq.2022.120132

D’Avila, F.G., Silva, C.M.F., Steckel, L., Ramos, A.C.S., and Lucas, E.F., Energy Fuel, 2020, vol. 34, no. 4, pp. 4095–4105. https://doi.org/10.1021/acs.energyfuels.9b04166

Kriz, P. and Andersen, S.I., Energy Fuel, 2005, vol. 19, no. 3, pp. 948–953. https://doi.org/10.1021/ef049819e

Tinsley, J.F., Jahnke, J.P., Dettman, H.D., and Prud’home, R.K., Energy Fuel, 2009, vol. 23, no. 4, pp. 2056–2064. https://doi.org/10.1021/acs.energyfuels.8b00664

Xue, H., Zhang, J., Han, S., Sun, M., Yan, X., and Li, H., Energy Fuel, 2019, vol. 33, no. 10, pp. 9570–9584. https://doi.org/10.1021/acs.energyfuels.9b01825

Ariza, E., Chaves-Guerrero, A., and Molina, V.D., Energy Fuel, 2018, vol. 32, no. 6, pp. 6557–6564. https://doi.org/10.1021/acs.energyfuels.8b00664

Ganeeva, Y.M., Yusupova, T.N., and Romanov, G.V., Russ. Chem. Rev., 2011, vol. 80, no. 10, pp. 993–1008. https://doi.org/10.1070/rc2011v080n10abeh004174

Kayukova, G.P., Petrov, S.M., and Uspenskii, B.V., Svoistva tyazhelykh neftei i bitumov permskikh otlozhenii Tatarstana v prirodnykh i tekhnogennykh protsessakh (Properties of Heavy Oils and Bitumens from the Permian Deposits of Tatarstan in Natural and Technogenic Processes), Moscow: GEOS, 2015.

Indad, Sh.S., Mukhamatdinov, I.I., Garifullina, E.I., and Vakhin, A.V., Neftegaz.RU., 2018, no. 4, pp. 102–106.

Abryutina, N.N., Abushaeva, V.V., Aref’ev, O.A., et al., Sovremennye metody issledovaniya neftei: Spravochno-metodicheskoe posobie (Modern Methods for Researching Oils: Reference Manual), Abryutin, N.N., Ed., Leningrad: Nedra, 1984.

Barskaya, E.E., Okhotnikova, E.S., Ganeeva, Y.M., and Yusupova, T.N., Petrol. Sci. Technol., 2023, vol. 41, no. 2, pp. 159–175. https://doi.org/10.1080/10916466.2022.2059083

Yusupova, T.N., Ganeeva, Yu.M., Romanov, G.V., and Barskaya, E.E., Fiziko-khimicheskie protsessy v produktivnykh neftyanykh plastakh (Physical and Chemical Processes in Productive Oil Reservoirs), Moscow: Nauka, 2015.

Unger, F.G. and Andreeva, L.N., Fundamental’nye aspekty khimii nefti. Priroda smol i asfal’tenov (Fundamental Aspects of Oil Chemistry. Nature of Resins and Asphaltenes), Novosibirsk: Nauka. Sibir. Izd. Firma RAN, 1995.

Tagirzyanov, M.I., Yakubov, M.R., and Romanov, G.V., J. Canad. Petrol. Technol., 2007, vol. 46, no. 9, pp. 1–5. https://doi.org/10.2118/2004-045

Wu, J. and Xu, Y., Fluid Phase Equilib., 2019, vol. 490, pp. 22–32.

Mousavi, M., Abdollahi, T., Pahlavan, F., and Fini, E.H., Fuel, 2016, vol. 183, pp. 262–271. https://doi.org/10.1016/J.FUEL.2016.06.100

Tinsley, J.F., Jahnke, J.P., Dettman, H.D., and Prud’home, R.K., Energy Fuel, 2009, vol. 23, no. 4, pp. 2056–2064

Freund, M., Csikós, R., Keszthelyi, S., and Mózes, G.Y.I., Chemical, Crystallographical and Physical Properties of Liquid Paraffins and Paraffin Waxes, in Paraffin Products Properties, Technologies, Applications, 1982, vol. 5, pp. 13–140. https://doi.org/10.1016/S0376-7361(08)70146-8

Tukhvatullina, A.Z., Barskaya, E.E., Kouryakov, V.N., Ganeeva Yu.M., Yusupova, T.N., and Romanov, G.V., J. Petrol. Environ. Biotechnol., 2013, vol. 4. https://doi.org/10.4172/2157-7463.1000152

ACKNOWLEDGMENTS

The authors are grateful to the researchers of the Multiple-Access Spectro-Analytical Center for Physical-Chemical Study of Structure, Properties and Composition of Substances and Materials, FRC Kazan Scientific Center of RAS, for their kind cooperation in the IR and EPR spectroscopy examination.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest requiring disclosure in this article.

Rights and permissions

About this article

Cite this article

Barskaya, E.E., Ganeeva, Y.M., Okhotnikova, E.S. et al. Viscosity–Temperature Properties of Model Oil Systems Rich in Asphaltenes and Paraffins. Pet. Chem. 63, 128–137 (2023). https://doi.org/10.1134/S0965544123020160

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544123020160